Five Advantages Of Products

- Superior performance

- Cost effective

- Long life and durability

- Easy installation

- Qualified with certificate

Product Details

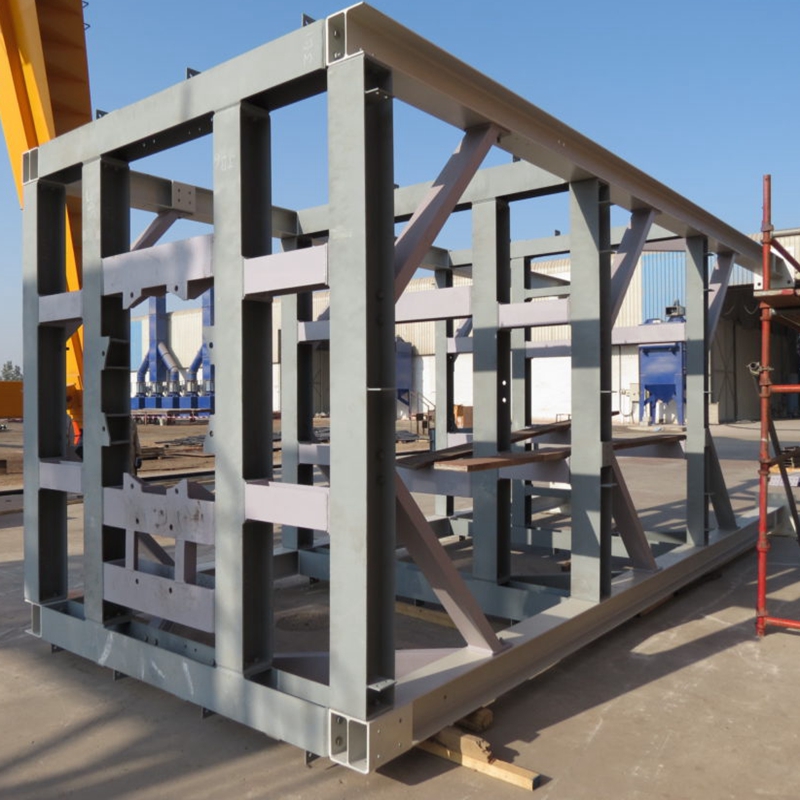

Module Mounting Structures are designed and engineered for each customer's site specific conditions to minimize the filed installation labor and require no filed welding, drilling or other on-site fabrication.

Why xinhuiying Solar Structures?

Easy and fast to assemble

25 years of maintenance free life

Cost effective

Optimal surface treatment for high corrosive resistance.

The structures are well protected against adverse climatic conditions

Xinhuiying Mounting Structure system is well designed, adhering to relevant Codal provisions, aesthetically pleasing, well tested and proven.

Xinhuiying Mounting Structure System is manufactured under controlled conditions, in "State-of-the Art" manufacturing systems, adhering to safety and superior quality parameters.

Due to unique profiles the structures can very easily be erected at site with even unskilled laborers.

Features:

Suitable for flat and slightly sloped roofs

Suitable for several module dimensions with a panel width from 950 to 1050mm

Total dead load of panels with steel structure and ballast below 10kg/m² of roof achievable

Standard and angle regulation from 5⁰C TO 30⁰C

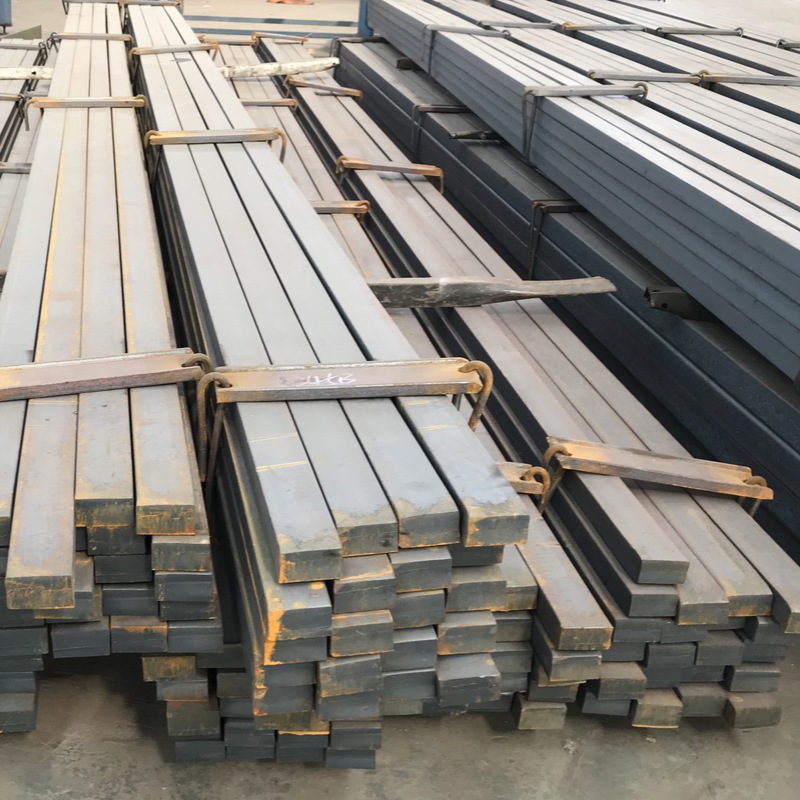

ZED and CEE Purlins, C Channels, bracings, angles and column post are members of Module Mounting structure. They can be pre-galvanized, post galvanized or made of Galvalume steel.

We provides galvanized steel for solar module mounting structure in the following specification:

Pre galvanized structure

Thickness: 0.8 to 3 mm

Material Yielding Sheet: 250 Mpa - 550 Mpa

Line Coating: 100 - 500 GSM

Material confirming to IS277

Post galvanized structure

Material Yielding Sheet: 250 Mpa - 350 Mpa

Hot dip galvanization up to 80 microns/ 550 GSM

Hot dip galvanization confirms IS2629

Galvalume Steel

Thickness 0.8 - 1.2 mm

Material Yielding Sheet: 250 Mpa - 550 Mpa

Aluminum Zing Coating: AZ - 70 / AZ – 150

Material confirms to ASTM, A792, SS80